Tech Tip: Exhaust Ventilation Modeling in eQuest

Relevant 90.1 Baseline Rules

G3.1.2.4 Fan System Operation: Supply and return fans shall operate continuously whenever spaces are occupied and shall be cycled to meet heating and cooling loads during unoccupied hours.

G3.1.2.9 System Fan Power: System fan electrical power for supply, return, exhaust, and relief for Systems 1 and 2:

Pfan = CFMs × 0.3

G3.1.2.5 Ventilation: Minimum ventilation system outdoor air intake flow shall be the same for the proposed design and baseline building design.

Exception to G3.1.2.5-3. Where the minimum outdoor air intake flow in the proposed design is provided in excess of the amount required by the building code or the rating authority, the baseline building design shall be modeled to reflect the greater of that required by either the rating authority or the building code and will be less than the proposed design.

Example 1: Continuous Exhaust + Trickle Vents

Proposed In-Unit HVAC:

PTACs that cycle with load to provide heating and cooling

PTAC fan power is 0.2 W/CFM, 2-speed fan

Continuous 100 CFM exhaust from kitchens and bathrooms via rooftop exhaust fan (EF) @ 0.4 W/CFM

Make-up air through trickle vents

Proposed Corridor HVAC

Roof-top unit (RTU) provides heating, cooling and ventilation to corridors

0.7 W/CFM RTU supply fan

Exhaust and make-up ventilation rates meet applicable codes (i.e. no over-ventilation penalty)

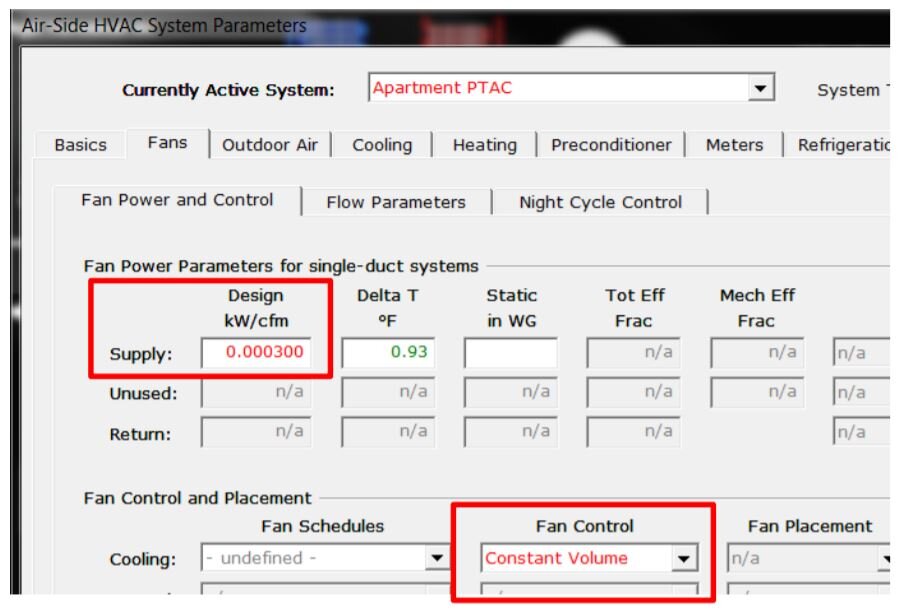

Baseline In-Unit PTAC Fan Power and Control

Baseline In-Unit PTAC Sizing

Baseline In-Unit PTAC Ventilation Rate

Set OA Air Flow (cfm) to 0.01 to force PTAC to run continuously (eQUEST work-around)

Enter exhaust as specified

Enter 0 W/CFM exhaust, since we allocated the full baseline fan power to PTAC supply fan (an acceptable simplification with negligible impact on results)

Set “Source” as shown, to indicate that make-up air is provided via balanced infiltration

Proposed Design: PTAC Fan Power and Control

Set PTAC fan power and control as specified

Proposed Design: In-Unit Exhaust Fans

Set exhaust fan power as specified

Set PTAC supply air flow to 0, to allow PTAC cycle with load

Proposed Design: Corridor RTU

Enter RTU fan power as specified

Example 2: Continuous Exhaust + Mechanical Supply Ventilation

Please note: Example 2 is based on eQuest build 7173 (DOE2.2).

Proposed In-Unit HVAC:

PTACs that cycle with load to provide heating and cooling

PTAC fan power is 0.2 W/CFM, 2-speed fan

Continuous 100 CFM exhaust from kitchens and bathrooms via rooftop exhaust fan (EF) @ 0.4 W/CFM

Make-up air through trickle vents

Proposed Corridor HVAC

Roof-top unit (RTU) provides heating, cooling and ventilation to corridors

0.7 W/CFM RTU supply fan

ducted to supply 60 CFM make-up air to each apartment

Exhaust and make-up ventilation rates meet applicable codes (i.e. no over-ventilation penalty)

Baseline HVAC

Same as above in Example 1, except:

In-unit supply CFM should be modeled as 60 OA CFM

Model RTU as PSZ system type instead of PTAC, to simplify modeling proposed design

Proposed In-Unit Systems

Enter in-unit exhaust fans, PTAC fans, and corridor RTU fans the same as in Example 1 above

RTU Make-up to Apartments

Reference the corridor RTU as the unit that supplies mechanical ventilation to apartments.

RTU OA CFM must be increased to include in-unit ventilation

Floors 2-10 each have 8 apartments; in order to supply 60 CFM OA ducted to each apartment, the corridor ventilation on these floors must be increased by 60 x 8 = 480 CFM

First floor has 4 apartments, so 4*60=240 CFM must be added to the

corresponding Thermal Zone (Parameter #3 below, not shown)

Impact on Energy Consumption (Example 1 & 2)

Similar changes in energy use between the baseline and proposed for both examples

Ventilation (fan) energy is the area of greatest impact

Savings strongly depend on efficient fan system design

Example 2 has slightly higher overall energy use for both the baseline and proposed design

Note: The examples demonstrate methods for modeling different ventilation designs. Additional inputs, such as specified supply flow rates, heating and cooling capacities for RTU and PTACs will be required to meet 90.1 requirements.